Precast Concrete Contractors Bring It Together!

Let’s build it together

How Precast helps you to bring your projects together

Precast Concrete General Contractors/Construction Managers (GC/CMs) are the symphony conductor for the construction project, coordinating deadlines, cost targets, and site logistics. Precast concrete is a preferred construction method because it makes scheduling and site management easier and safer.

Precast Simplifies Site Logistics

Reduced Storage, Increased Safety, One Material

A job site utilizing precast concrete eliminates the spatial constraints that other construction methods require on-site. All components are poured off-site in a controlled environment and placed on a trailer ready to be erected. A crane is used to pick and place the precast pieces onsite. This reduces the need for storage and build-on-site space.

When placing panels and precast elements, only one smaller crew is needed on-site during this phase of the project. As a result, there is less opportunity for injury and lost work time.

In addition, built-off-site precast components eliminate the need for additional on-site trade workers. This is accomplished by the installation of insulation, fireproofing, windows, and electrical components into the precast panel.

Time-to-Completion

Speed of Construction through parallel builds

Utilizing precast off-site-build has many advantages:

- While a construction site preparation is in process, precast components are completed and loaded onto trailers for delivery to the construction site.

- Specify insulation, masonry, fireproofing, electrical, and external finishes to save on-site build time and cost.

- An average of 12-16 precast components can be placed in a day! As a result, a completely enclosed structure will be up in no time. (results can vary depending on panel design and project size).

- Precast elements are made indoors preventing weather from driving the schedule.

- Precast adds structural integrity to the overall building project, making the site safer sooner.

How Precast Saves Money

Where does the cost go?

Precast concrete construction is divided up into three main cost buckets. Each bucket is an average and can vary depending on the difficulty, scale, and location of the project.

- Product: Labor, Materials, Finishing, and Engineering

- Transportation: Trucking, Toll, and Bridge Fees, Escort Vehicles, and Permits

- Site Logistics: Size, Grade, and Affect on Erection

Consider the benefits of precast concrete and the long-term cost savings associated with this construction material. Some examples to consider are thermal efficiency, the potential for built-in insulation, and the elimination of additional tradespeople, minimizing construction time.

Resources for Developers

Featured Projects for Developers

Christ Hospital

In 2012, the Christ Hospital Network in Cincinnati, Ohio, decided to add an orthopedic center of excellence to its already nationally renowned healthcare facility. The owners worked with an architect to design the seven-...

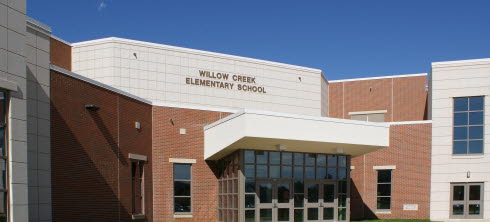

Willow Creek Elementary

The two-story, 108,000 ft2 Willow Creek Elementary School was built in response to increased enrollments at the elementary school level. The school opened for the 2009-2010 academic year and features 44

Penn State Hershey Campus Parking Garage

Inspired by the rolling hills in Pennsylvania, the eye-catching waving spandrels are the first element to greet you as you drive onto the health campus and the last

80 on the Commons

The playful yet sophisticated use of a herringbone pattern results in a standout, bold style that NBBJ wanted to capture on this civic asset in the city’s central open space.

ELEVATE YOUR PRECAST DESIGN.

Have a question about our precast design options? That's what we are here for. Reach out to our team of precast design engineers with any questions or details about your project and we will get back to you.