Architectural Precast Concrete

Architectural Precast Concrete

Architects have chosen precast concrete architectural facades for more than half a century because they offer exceptional aesthetic and structural versatility, speed of enclosure, and durability. No other material combines the range of shapes, colors, textures, fire-resistance, acoustical insulation, weather tightness, long-term durability, low maintenance care, and rapid enclosure.

The aesthetic design versatility of wall panels allow for complex and beautiful buildings to emerge using two types of wall panels:

-

Load Bearing Architectural Wall Panels

-

Non-Load Bearing Architectural Wall Panels

Both Panels can be either insulated or solid wall panels.

Precast wall panels include weather-tight enclosures for maximum protection against mold and mildew, and their superior structural strength makes them highly impact- and blast-resistant for maximum security. The durability of our wall panel systems makes them the ideal choice for meeting long-term construction needs.

Meet A Representative

Alexandra "Ace" Clayton

Business Development

Mobile: 717.538.8078

Architectural Literature

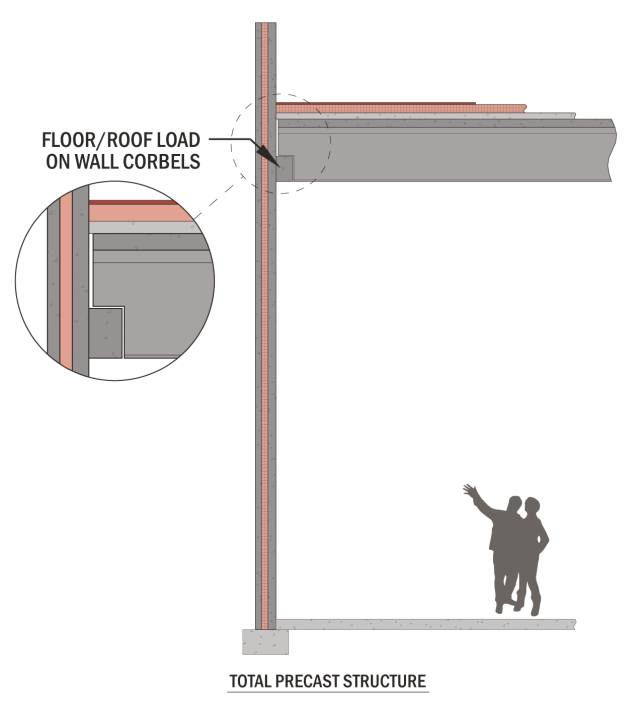

Load Bearing

These panels are more than an external shell to a building, load-bearing wall panels transfer floor and roof loads through the panels down to the foundation. The panels can also transfer horizontal loads to shear walls.

Architectural Cladding

These panels act as an external shell to the building and can be load-bearing or non-load bearing. They attach to the superstructure of the building and provide a sealed external cladding that is more decorative and protective against the external elements.

Insulated Panels

Insulated panels act as a barrier system providing thermal efficiency and a face-sealed water barrier. With three layers of beautiful cohesiveness, you are able to achieve a decorative finish for any design look, insulation that meets more stringent building code requirements, and back concrete wythe with a sealed finished wall. To connect the three wythes you use what is called a wythe connecter. Pins connect the face wythe and the rigid insulation providing a grid of connectors across the body of the panel.

Utilizing insulated panels helps site efficiency aiding in the speed of construction, minimal clutter, and a safe work environment. The panels are durable and long lasting making them a low maintenance option. They provide a continuous edge-to-edge insulation, ashire 90.1 and 2012 international energy conservation code.

Solid Panels

Strictly composed of precast concrete and are at a minimum of 6" thick. Reveals, articulation, decorative accents, and mix designs are available to meet all your design requirements. This style of paneling can be both load-bearing and non-load bearing but does not have the ability to meet as beneficial thermal efficiency as an insulated panel.

Swipe on the image or use the arrow to see more example buildings.

CarbonCast® Panels

C-GRID carbon fiber reinforcing is the "enabling technology" that allows CarbonCast to be thinner, lighter, more durable, and less costly than conventional precast. Non-corrosive and with low thermal conductivity, C-GRID has a tensile strength over four times higher than steel reinforcing. C-GRID is an epoxy-coated composite grid made with cross-laid and superimposed carbon fiber.

While the C-GRID carbon fiber reinforcing product is a bit more expensive than traditional reinforcement products, it does offer other important cost-saving benefits. Specifically, by allowing for upgrades in the precast design used in the manufacturing of CarbonCast components.

Components

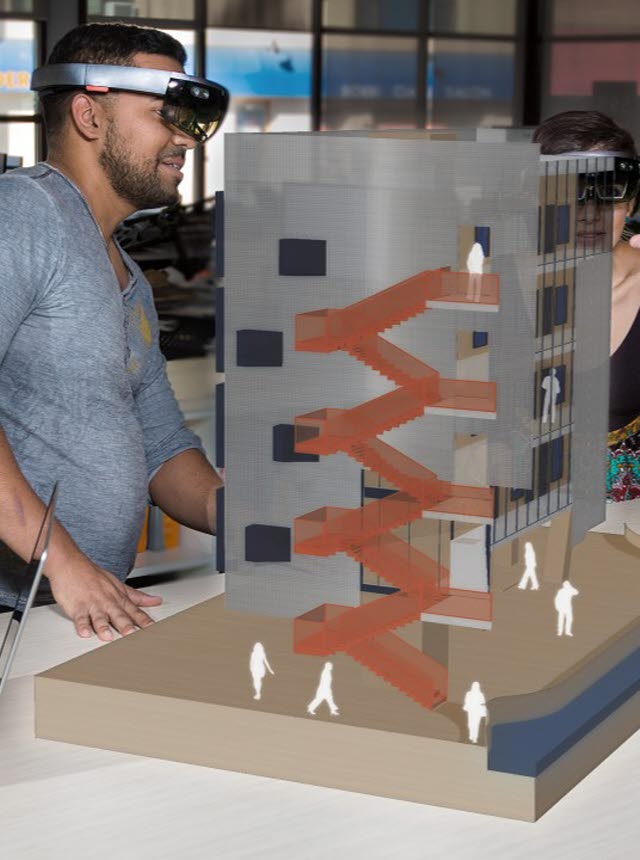

An architectural building can be composed of elements that we produce both in Springboro, OH, and also in Denver, PA. Each precast concrete element on the image to the left is highlighted with the appropriate term.

Click on the blue dots on the picture to the left to learn more about the precast components.

Resources

Architectural Enclosure FAQs

Can curved panels, or unusually shaped panel profiles be created economically?

Yes, but only if shapes are repetitive. It costs considerably more to create an original mold (or form) for complex shapes/profiles. However, if 20 to 30 castings are made from a single mold, the cost is amortized over all of the castings, reducing the premium to a nominal amount per casting.

What are the keys to color uniformity?

There are numerous ways in which precast color uniformity can be enhanced.

The goal is to have color uniformity, but any concrete, depending on color and mix can vary. The finish of concrete also can add in an additional variant. High Concrete Group follows the PCI regulations on the color range.

All non-earth tone colors (blue, green, red, yellow) are the most difficult to keep a closer color variation than earth tones (gray, tan, white).

There are numerous ways in which precast color uniformity can be enhanced.

Use a retarded finish. This exposes the coarse aggregate, permitting the coarse aggregate's uniform natural color to "carry" the panel's color. In doing so, be certain to use a color compatible matrix (sand/cement/pigment), in order to mask any uneven coarse aggregate dispersion.

Use white cement instead of gray cement whenever possible. White cement's color control is excellent. Gray cement manufacturers do not attempt to control color. Thus, gray cement color can vary widely even within a single SUPPLIER, causing significant precast color variations.

Remove a sufficient amount of the as-cast concrete's surface. All concrete is blotchy when left as-cast. The surface "paste" or "skin" must be removed in order to reveal the true concrete color. For example, light acid etching is apt to result in a blotchy or shaded appearance because the acid does not remove all of the surface "paste" or "skin". Therefore, acid-etched finishes should be deep enough to reveal the tips of the coarse aggregate. Likewise, lightly sandblasted finishes should reveal some coarse aggregate, in order to appear reasonably uniform.

Avoid large planes of smooth, uninterrupted surfaces. If the eye has nothing to focus upon except large expanses of plain, smooth concrete surfaces, it will perceive minute panel to panel color differences. If instead, such large surfaces are interrupted by rusticated joint patterns, plane changes, and/or mix/finish changes, the eye will be drawn to these features making slight color variations, panel to panel, almost indistinguishable and unimportant.

Avoid using pigments in very small dosages. Pigment content, as a percentage of the total ingredients in a concrete batch, is very small. As that percentage diminishes, the likelihood of increased pigment content variation, batch to batch, goes up dramatically causing noticeable color variation.

Will using multiple mixes and/or finishes in a single project increase my precast cost dramatically?

Multiple mixes will increase cost. Consult your High representatives before finalizing your design, because some mix and/or finish combinations require more additional labor than others.

Should I avoid creating small precast pieces, or, instead, make them part of larger pieces where possible?

Small precast pieces usually cost much more per square foot than large pieces (pieces 100 sq. ft. or larger) because handling costs (i.e., stripping, finishing, yarding & loading, hoisting and connections) are similar for small and large pieces. The cost for handling small pieces is distributed over fewer square feet per piece than in large panels so that the handling cost per square foot for small panels is greater than for large panels. Where possible, combine small pieces with adjacent precast pieces.

What should I do to ensure the look I want at an affordable cost?

The most important thing you can do is call 1.800.PRECAST to involve your HCG representative as early as possible in the development of your project's architectural precast application. Our sales representatives are trained to help designers maximize the value of their precast design. For example, how a precast exterior is panelized can affect cost significantly with little or no difference in appearance. Also, a designer can employ important features such as reveals, rustication joints, medallions, form liner patterns, etc. at very little additional cost, but only if such features are used repeatedly (avoiding costly, frequent form changes). It's important to know what design techniques to use and when to use them. Contact your High sales representative.

How important is PCI certification for me as a designer?

We are certain that you, as well as your client, expect your building's exterior to become the high quality realization of your design's intent. And the best assurance that your project will be a high quality result is to rely upon the industry's only truly independent certification program - PCI's plant certification program.

Why should I design with architectural precast, and what makes it my best option?

There are four (4) compelling reasons to choose architectural precast concrete for your building's exterior:

1. Architectural precast is the only cladding material that permits you, the designer, to custom design shape, color, texture, and pattern - only you control your building's unique, custom exterior look.

2. Architectural precast enables you to enclose your building's exterior in a small fraction of the time versus most all other cladding materials - this reduces construction cost dramatically and provides your client much earlier occupancy.

3. Proven low initial cost. Architectural precast concrete is used widely by office building developers nationwide. They tell us it is their cladding material of choice because it offers a high quality "look" at a very economical price.

4. Long term maintenance is almost negligible. All you need to do is re-caulk the precast joints after 15 to 20 years.

Can architectural precast be used as a load-bearing element?

Certainly! We encourage you to do so. For a minimal additional cost (some additional reinforcing and minor additional connection cost) architectural precast concrete can become a terrific load-bearing element.

Related Projects

Riverside Hospital Neuroscience Tower

The Riverside Hospital Neuroscience Tower project is a 10-story, 437,000-square-foot addition to an Ohio Health campus. The project is the only one of its kind

Christ Hospital

In 2012, the Christ Hospital Network in Cincinnati, Ohio, decided to add an orthopedic center of excellence to its already nationally renowned healthcare facility. The owners worked with an architect to design the seven-...

80 on the Commons

The playful yet sophisticated use of a herringbone pattern results in a standout, bold style that NBBJ wanted to capture on this civic asset in the city’s central open space.

1200 Intrepid

2016's Harry H. Edwards Industry Advancement Award winner proves that precast concrete enables the most innovative architectural designs while providing a highly energy-efficient and durable envelope. One of

ELEVATE YOUR PRECAST DESIGN.

Have a question about our precast design options? That's what we are here for. Reach out to our team of precast design engineers with any questions or details about your project and we will get back to you.