Precast Concrete Sustainability

Sustainability of Precast Concrete

Innovative Building Solutions

After water, concrete is the most widely-used substance on the planet. From infrastructure and transportation to commercial buildings and residential uses. Concrete is the foundation of modern development, safeguarding against natural disaster and providing a structure for healthcare, education, transport, energy and industry. Now, more than ever, both private and public entities are increasingly looking to implement impactful sustainability solutions for both the construction and operation of buildings. With nearly 40% of energy-related carbon emissions produced by the global building sector, owners, investors, architects, and general contractors are increasingly turning to precast concrete to enhance the resiliency and sustainability of the built environment.

In the first of two blog posts on sustainability, we’ll dive into the definition of sustainability and how the precast concrete industry and High Concrete Group are actively working to reduce carbon emissions and improve sustainability practices.

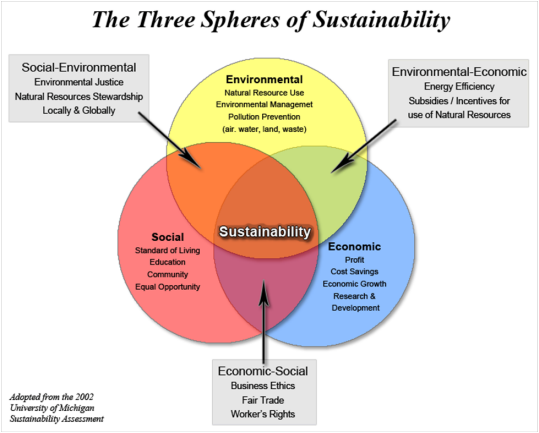

Spheres of sustainability and examples

Defining Sustainability

First, it is important for us to establish what makes something sustainable. The essence of sustainability is that it enables a balance to be maintained between people and the environment. Sustainable practices ensure that human, environmental, and financial needs are protected. A holistic approach to sustainability focuses on all of these areas.

Human Needs

While environmental impact is important for a company to consider, ensuring the wellbeing of the people within and around the company is also important. This is why, in our sustainability efforts, we are proud of how the High Foundation supports the surrounding community.

High Concrete Group aligns within the High Industries side of the High Companies business, and in March 2022 ownership of High Industries was transferred from the High family to The High Foundation. As majority stakeholder, the High Foundation is now capable of distributing the profits from High Industries back into the communities in which their co-workers live and work. It’s the ultimate commitment to social responsibility and doing business for good in an impactful and lasting way. Founded in 1980, The Foundation’s core areas of giving are inspired by the call to extend ourselves for the common good to solve problems in the areas of education, housing, transportation, healthcare, financial literacy, childcare, nutrition and more.

Financial Needs

Concrete by nature is affordable and renewable due to the abundance of materials needed to produce it. The use of aggregates allows for flexibility in which kinds of stone, gravel, sand, etc. can be used. Unlike traditional building materials that require more specific sources, such as wood or masonry, concrete can often be produced with recycled or locally sourced materials. Even types of industrial waste can be used in concrete production. At High Concrete Group, we are finding new ways to reduce emissions through our concrete mixes. We utilize a low water-to-cement ratio along with a significant amount of recycled slag.

Precast concrete is also unique in its ability to create minimal waste products. Compared to traditional cast-in-place concrete, there is less risk of producing excess or potentially wasting material that might begin to harden before being poured. Producing pieces in a controlled environment allows for more accurate estimates of needed material, along with the ability to pour at the same location where the concrete is mixed.

Environmental Needs

Precast concrete structures are highly effective at maintaining stable indoor environments. Panels reduce noise from outside and are energy efficient. There are many options for designing precast panels that are insulated in order to reduce HVAC usage. This is both cost-effective for building occupants and better for the environment by consuming less electricity. In combination with these benefits, High Concrete only works with subcontractors who have strong sustainability goals in order to align the entire supply chain, from design to final product, with our values.

Building a structure consumes large amounts of both energy and material. If buildings are designed and engineered to last, there is far less environmental impact from having to rebuild homes, retail, schools, or offices every few years. Precast concrete can have extremely high longevity due to its durable properties. In areas with harsh weather conditions, precast structures can withstand temperatures, storms, or seismic activity that would otherwise be devastating.

Because precast concrete pieces have such longevity, it is also important to note that these panels can be taken apart and reused. If a structure’s use changes or expansions are needed, parts of it can be removed without the need for demolition. The pieces can then be reincorporated back into the structure or repurposed in a different building. This element of precast makes it a very sustainable option from a long-term perspective. It reduces the need for demolition of entire structures, and it gives designers more flexibility for expansions or renovations.

Simply by using precast concrete, structures can quickly qualify for LEED certification. The nature of the material itself, along with special considerations that can be taken when producing it, can automatically make a precast structure more sustainable than many alternatives.

Sources:

https://precast.org/sustainability-and-practicality-of-precast-concrete/

Recycled concrete can be used in a variety of applications

Reach Out to Our Team